ENERGY & ENVLRONMENT

PRODUCTS

By replacing Brown Gas instead of cutting fuel (LNG + preheated oxygen), it improves the cutting speed and the cutting width (Loss) to significantly reduce dust,

thereby improving the environment and reducing costs.

[ER-200K cutting system]

[NER-23K cutting site,Japan Nisshin Steel]

[600mm Tundish cutting]

See video

[250mm cold slab cutting]

See video

[810mm SCM cutting]

See video

[250mm hot slab cutting]

See video

[Cylinder cover cutting]

See video

[Round rod bundle cutting]

Delivery record

| CUSTOMER | YEAR | DESCRIPTION |

| POSCO Scrap yard (Gwangyang, Korea) | 2006 | Thickness 700mm Tundish blocks, Scraps cutting : 10Nm3/h Brown Gas Generator 10Set |

| POSCO 2nd TCM Plant (Gwangyang, Korea) | 2007 | Thickness 250mm Hot Slab cutting : 10Nm3/h Brown Gas Generator 12Set |

| POSCO Special Steel co. (Changwon, Korea) | 2010 | Thickness 1,000mm Tundish blocks, Scraps cutting : 21.5Nm3/h Brown Gas Generator 4Set |

| Saea Besteel(Gunsan, Korea) | 2012 | Thickness 1,000mm Ingot, Scraps cutting : 21.5Nm3/h Brown Gas Generator 4Set |

| Nishin Steel(Japan) | 2012 | Thickness 220mm Stainless, Slab cutting : 10Nm3/h Brown Gas Generator 1Set |

| Taeyang Machinery (Japan) | 2013 | Thickness 250mm Slab cutting : 10Nm3/h Brown Gas Generator 1Set |

| Okumurakumi (Nippon Steel Partner, Japan) | 2015 | Thickness 1.500mm Pig Iron : 21.5Nm3/h Brown Gas Generator 4Set |

| SCE Group (Australia) | 2017~2018 | Thickness 250mm Slab cutting : 4.6Nm3/h Brown Gas Generator 5Set |

| Stein Group (USA) | 2018 | Thickness 250mm Slab cutting : 4.6Nm3/h Brown Gas Generator 2Set |

| Ganji co. (China) | 2018 | Thickness 250mm Slab cutting : 4.6Nm3/h & 10Nm3/h Brown Gas Generator each 1Set |

| E&E (Shanghai) Corporation (Qinghuan huanbao) | 2020~2021 | Thickness 600mm Tundish blocks, Scraps cutting : 21.5Nm3/h Brown Gas Generator 3Set |

| BAO STEEL Transport Section (Shanghai) | 2022.12 | Thickness 500mm Scraps cutting : 21.5Nm3/h Brown Gas Generator 11Set |

| BAO Steel 1st Steelmaking Section (Shanghai) | 2022.12 | Thickness 1.500mm Slagsteel (Materials in which refractories and iron are mixed) cutting : 21.5Nm3/h Brown Gas Generator 3Set |

| BAO Steel 2nd Steel making Section (Shanghai) | 2023.03 | Thickness 1.500mm Slagsteel (Materials in which refractories and iron are mixed) cutting : 21.5Nm3/h Brown Gas Generator 4Set |

| Nanqing Steel (China) | 2023.03 | Thickness 1.500mmSlagsteel (Materials in which refractories and iron are mixed) cutting : cutting : 21.5Nm3/h Brown Gas Generator 4Set |

| Nanqing Steel (China) | 2023.06 | Thickness 1.500mmSlagsteel (Materials in which refractories and iron are mixed) ) cutting : cutting : 21.5Nm3/h Brown Gas Generator 4Set |

By reducing the cutting width, the amount of fume generated can be reduced to 50 to 80%, improving the working environment and reducing dust collection equipment.

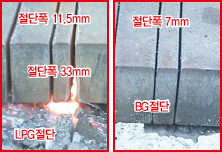

[LPG Cutting site]

[Brown Gas Cutting site]

It is possible to reduce costs by improving productivity and reducing cutting width.

Reducing cutting width [LPG vs Brown Gas]

[Comparison of 250mm slab cutting]

[Reducing 67% of cutting width of

650mm carbon alloy steel]

[Reducing 54% of cutting width of

140~200mm Stainless steel tundish slug

250mm Hot slab cutting comparison table [LNG vs Brown gas]

| Contents | LNG+Preheating oxygen | Brown Gas | Remarks |

| One cutting time | about 23.05min | about 13.92min | About 1.8 times productivity improvement |

| High pressure consumption | 35.35Nm³ (11.5 Bar) | 17.50Nm³ (10 Bar) | Saving of over 60% of oxygen when not using preheated oxygen and considering cutting speed |

| Cutting width(Loss) | 20mm | 11mm | Reduction of cutting width of 45% and fume generation more than 50% |

250mm Hot slab cutting comparison table [LNG vs Brown gas]

| Contens | LNG | Brown Gas | Remarks |

| Cutting speed | 250mm/min | 460mm/min | 1.8x Faster |

| Cutting width(Loss) | 9~10mm | 6~7mm | 30% Save |

| Step | Steps are generated by using two torches | Step is not generated by using one torch | - |

| Fume generation | Massive occurrence | small occurrence | 70% Decrease |

| Environmentality | CO2 occurrence | No CO2 occurrence | - |

| Safety | Choking and explosion hazard | No choking and explosion hazard | - |

220mm Stainless steel cutting comparison table [LNG vs Brown gas] / (Unit : CNY)

| CONTENSTS | POSCO | E&E | Economic efficiency compared to LNG | ||

| Economic efficiency | LNG | 2.8486 元/N㎥ |

0.167 N㎥/min(= 10N㎥/h) x 3.125min/15.642ton x 2.8486CNY/N㎥= 0.095CNY/ton - Cutting speed : 320mm/min - 1,000mm (= 1m) Cutting time : 3.125min - Cutting amount : about 1.1Mton/year (Average length 9m x Average width 1m x Thickness 0.22m x STS specific gravity 7.9)/Cut = 15.642ton/Cut 15.642ton/Cut x 5.5Cut/charge = 86.031ton/charge 86.031ton/charge x 1,064charge/month x 12month/year = about 1.1Mton/year |

0CNY/ton | (-) 0.095CNY/ton |

| Brown Gas | 2.318 元/N㎥ | 0CNY/ton |

0.25N㎥/min (= 15N㎥/h) x 2min/15.642ton x 2.318CNY/N㎥ = 0.074CNY/ton - Cutting speed : 500mm/min - 1,000mm (= 1m) Cutting time : 2min - Brown Gas Price : 3.9KWh/N㎥ x 0.5943CNY/KW h = 2.318CNY/N㎥ |

(+) 0.074CNY/ton | |

| Oxygen (High pressure, Pre-heat) |

0.7318 元/N㎥ |

High pressure : 0.833N㎥/min(= 50N㎥/h) x 3.125min/15.642ton x 0.7318CNY/N㎥ = 0.12CNY/ton Pre-heat : 0.042N㎥/min(= 50N㎥/h) x 3.125min/15.642ton x 0.7318CNY/N㎥ = 0.006CNY/ton |

High pressure : 0.67N㎥/min(= 40N㎥/h) x 2min/15.642ton x 0.7318CNY/N㎥ = 0.063CNY/ton Pre-heat: 0CNY/ton |

(-) 0.063CNY/ton (50% Reduction) |

|

| Total energy cost | 0.221CNY/ton | 0.137CNY/ton |

(-) 0.084CNY/ton (38% Reduction) |

||

| Iron powder | about 30 CNY/Kg | (0.23Kg/min x 3.125min)/15.642ton = 0.046Kg/ton 0.046Kg/ton x about 30CNY/Kg = 1.38CNY/ton |

(0.16Kg/min x 2min)/15.642ton = 0.020Kg/ton 0.020Kg/ton x about 30CNY/Kg = 0.60CNY/ton |

(-) 0.78CNY/ton (56.5% Reduction) |

|

| Cutting loss area | Cutting loss area: 3,630mm²/Cut ※ Upper cutting length : 13mm, Lower cutting length : 20mm |

Cutting loss area : 1,210mm²/Cut ※ Upper cutting length : 5mm, lower cutting length : 6mm |

(-) 2,420mm²/Cut (66.7% Reduction) |

||

| Environmental effect | Brown Gas reduces dust generation by about 70% compared to LNG, which significantly reduces the maintenance cost of dust collection equipment and improves the working environment. | ||||

COMPANY : E&E CEO : HYUN JANG SOO, YANGSOOK JUNG TEL : +82 31 354 0670 FAX : +82 31 354 3690

E-MAIL : ene06700690@daum.net ADDRESS : 599, 3.1manse-ro, Paltan-myeon, Hwaseong-si, Gyeonggi-do, Korea, Zip code : 18578

COPYRIGHT ©E&E All RIGHTS RESERVED.